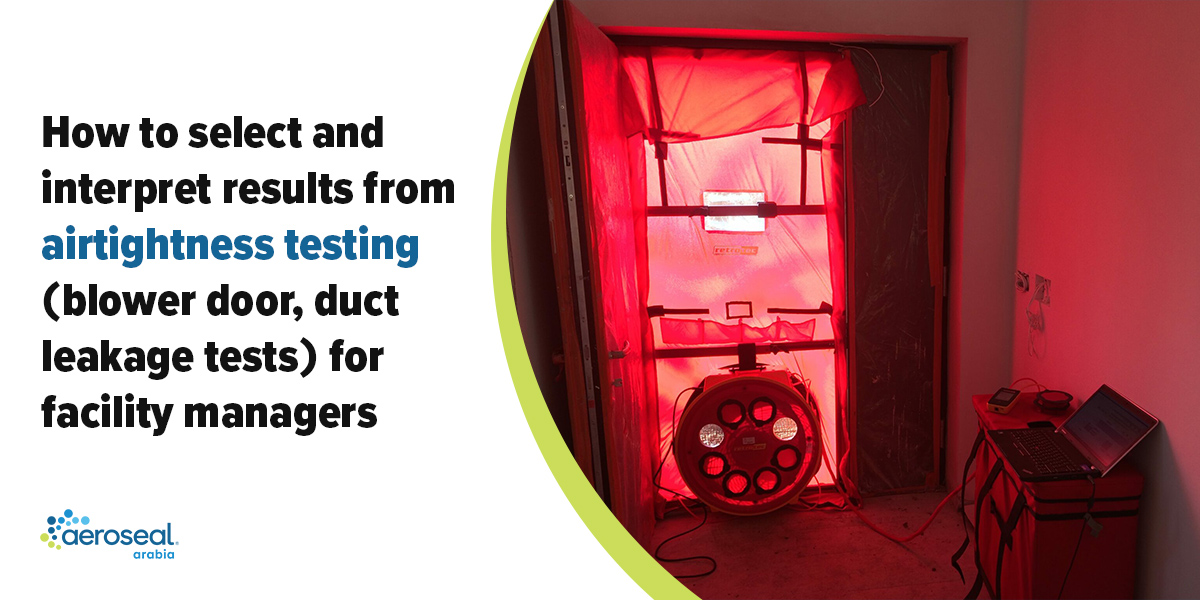

How to Select and Interpret Results from Airtightness Testing for Facility Managers

For facility managers in Saudi Arabia, airtightness testing is no longer a niche technical exercise. It is a critical tool for controlling energy costs, improving HVAC performance, and meeting building code and sustainability requirements. Tests such as blower door testing and duct leakage testing provide measurable data, but their value depends on selecting the right test and correctly interpreting the results.

This guide explains how facility managers can choose the appropriate airtightness tests and understand what the results actually mean for building performance, operating costs, and corrective actions.

Why Airtightness Testing Matters for Facility Management

In hot climates like Saudi Arabia, uncontrolled air leakage significantly increases cooling loads. Even well-designed HVAC systems struggle to perform when conditioned air escapes or hot outdoor air infiltrates the building.

Airtightness testing helps facility managers:

Identify hidden energy losses

Verify building and HVAC performance

Reduce cooling demand and electricity bills

Support compliance with SBC and sustainability programs

Improve indoor air quality and occupant comfort

Without testing, most decisions are based on assumptions rather than measured performance.

Understanding the Two Key Airtightness Tests

Facility managers typically rely on two main tests, each serving a different purpose.

Blower Door Testing Explained

A blower door test measures how airtight the building envelope is. A powerful fan is temporarily installed in an exterior door to pressurize or depressurize the building. Sensors then measure how much air leaks through walls, roofs, windows, doors, and other envelope components.

What this test tells you:

Overall envelope air leakage

How much uncontrolled outdoor air enters the building

Whether the building meets airtightness targets or code requirements

Blower door testing is especially important for:

Commercial buildings

Healthcare and education facilities

High-efficiency or green-certified projects

New construction and major retrofits

Duct Leakage Testing Explained

Duct leakage testing focuses specifically on HVAC ductwork. It measures how much conditioned air is lost through leaks in supply and return ducts before it reaches occupied spaces.

What this test tells you:

Percentage of air lost through duct leaks

Impact on airflow delivery and system balance

Reasons for high HVAC energy consumption

This test is critical in Saudi buildings, where duct leakage can reach 20 to 40 percent if not properly sealed.

How to Select the Right Test

Facility managers should select tests based on the problem they are trying to solve.

If energy bills are high and cooling performance is poor across the building, start with a blower door test to evaluate the envelope.

If some zones are too hot or too cold, airflow is weak, or HVAC systems run continuously, duct leakage testing is essential.

In many cases, both tests are needed. A building can have a tight envelope but leaky ducts, or sealed ducts inside a highly leaky structure. Only testing provides clarity.

Key Metrics Facility Managers Must Understand

Test reports include technical numbers that are often misunderstood. Knowing what they mean helps you make informed decisions.

Air Changes per Hour (ACH)

ACH indicates how many times the building’s air volume is replaced per hour at a specific pressure, usually 50 Pascals.

Lower ACH values mean better airtightness

Higher ACH values indicate excessive leakage

For many commercial buildings, lower ACH directly translates into lower cooling demand and better pressure control.

CFM Leakage Values

CFM measures how much air is leaking, expressed in cubic feet per minute.

In blower door tests, it shows total envelope leakage

In duct leakage tests, it shows how much air escapes the duct system

Facility managers should focus on how these values compare to building size and design expectations, not just absolute numbers.

Leakage as a Percentage of Airflow

In duct testing, leakage is often shown as a percentage of total system airflow.

Below 5 percent indicates high-performing duct systems

10 percent or higher signals major energy waste

High percentages usually justify immediate duct sealing.

How to Interpret Results Correctly

Airtightness results should always be interpreted in context.

A building that technically meets code limits may still perform poorly if HVAC systems are oversized or pressure is poorly balanced.

Compare test results with:

Energy consumption data

Cooling complaints and comfort issues

Humidity levels and indoor air quality reports

If airtightness results improve but energy use remains high, airflow balancing or system controls may need attention.

Turning Test Results into Action

Testing without corrective action has little value. Facility managers should use results to define clear next steps.

High envelope leakage calls for targeted envelope sealing, especially around roofs, façades, service penetrations, and window interfaces.

High duct leakage requires duct sealing solutions. Advanced internal sealing technologies can address leaks without opening ceilings or disrupting operations.

After sealing, re-testing is essential to confirm improvement and document performance gains.

The Importance of Post-Sealing Verification

Facility managers should always require before-and-after testing.

Verification confirms:

Actual reduction in air leakage

Improvement in HVAC efficiency

Justification for energy savings claims

Support for audits, certifications, and compliance

This data is also valuable for long-term asset management and budgeting.

Common Mistakes Facility Managers Should Avoid

Relying on visual inspections instead of testing

Assuming new buildings are automatically airtight

Ignoring duct leakage because it is hidden

Failing to re-test after repairs or sealing

Treating test reports as paperwork instead of performance tools

Avoiding these mistakes protects both operational budgets and building longevity.

Conclusion

For facility managers, airtightness testing is one of the most powerful tools for understanding and improving building performance. Selecting the right test and correctly interpreting the results allows you to reduce cooling costs, improve comfort, extend HVAC lifespan, and meet regulatory and sustainability goals.

Blower door testing reveals how the building envelope performs, while duct leakage testing shows how efficiently HVAC systems deliver conditioned air. Together, they provide a complete picture of where energy is lost and how to fix it.

In Saudi Arabia’s demanding climate, airtightness testing is not just a technical check. It is a strategic facility management decision that delivers measurable, long-term value.